EdingCNC Software

Our software has been developed over 10 years with input and feedback of actual users of CNC equipment. We feel the result is an easy-to-use interface that enables CNC operators to accomplish their tasks.

We are working daily on improving and adding new features to our software. Just to show you some of the many advanced features we have perepared here for you a small list prepared….but of course to really experience our product try to download the software HERE.

- Shortest possible CNC production time, especially 3D work, depending on the product, EdingCNC can be up to 2 times faster . This is thanks to the advanced Look Ahead Feed Algorithm that works for all motion segments, lines and circles by looking at their curvature and reduce speed only when absolutely necessary.

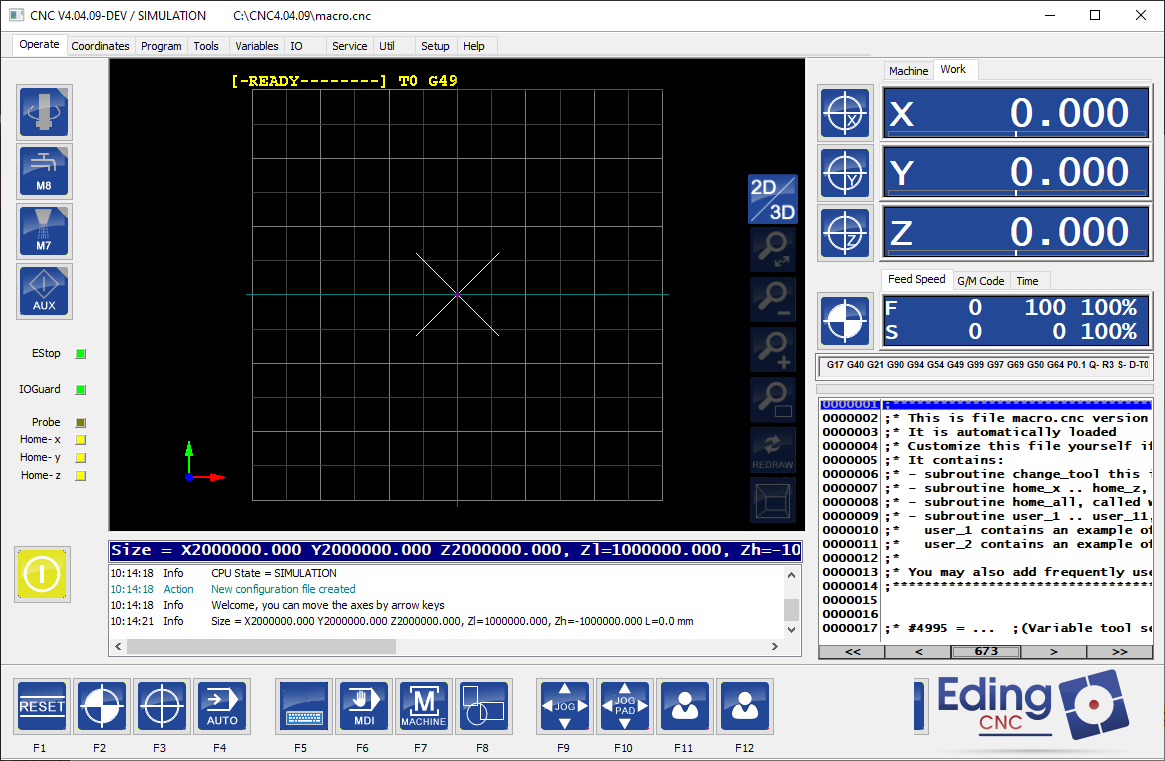

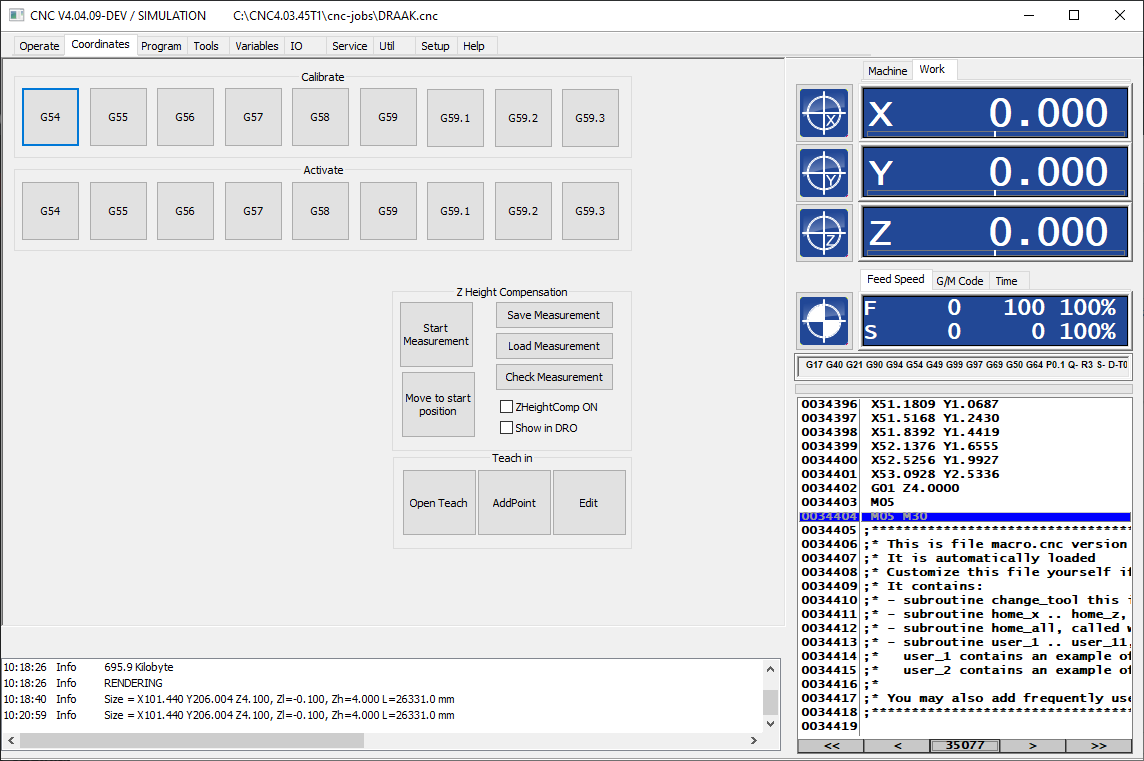

- Simple one-screen operation, UI designed for and by professional CNC operators.

- Nesting mode execution for multiple productions.

- Optimized tooltip feed calculations for 4th axis milling, no tool breakage due to wrong tool-tip feed.

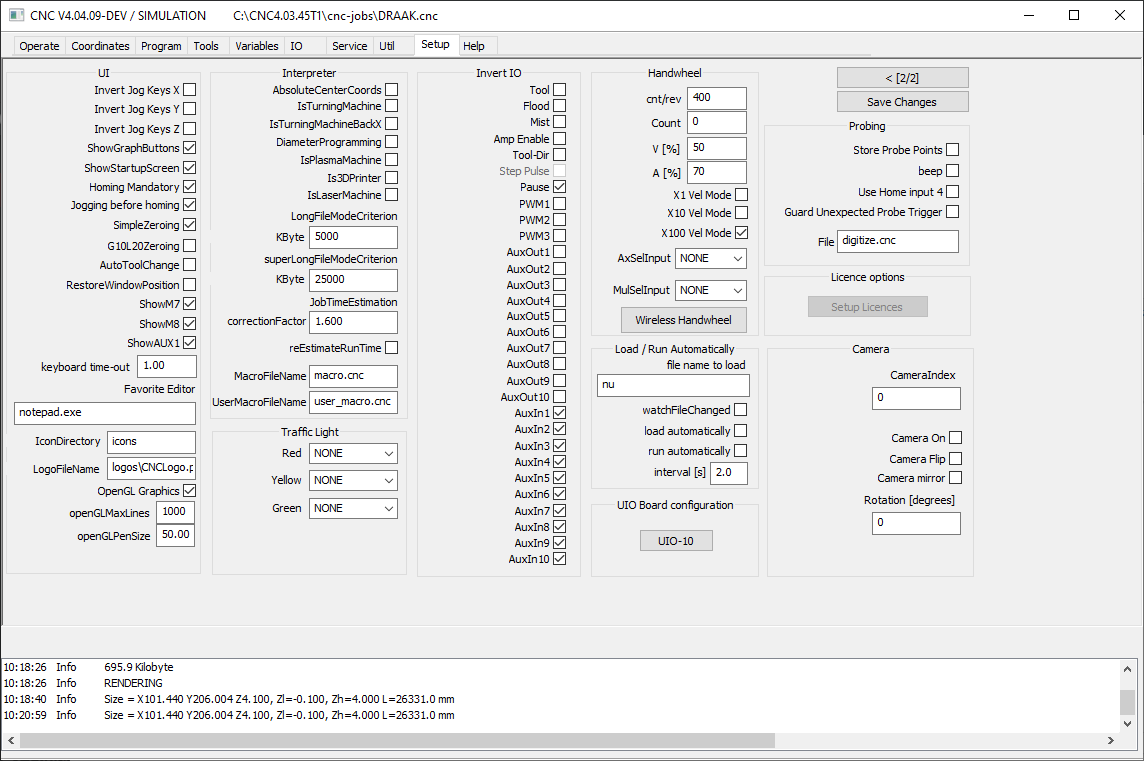

- Feed Override control while running 0-300%.

- Easy start halfway in the g-code file, using the search method

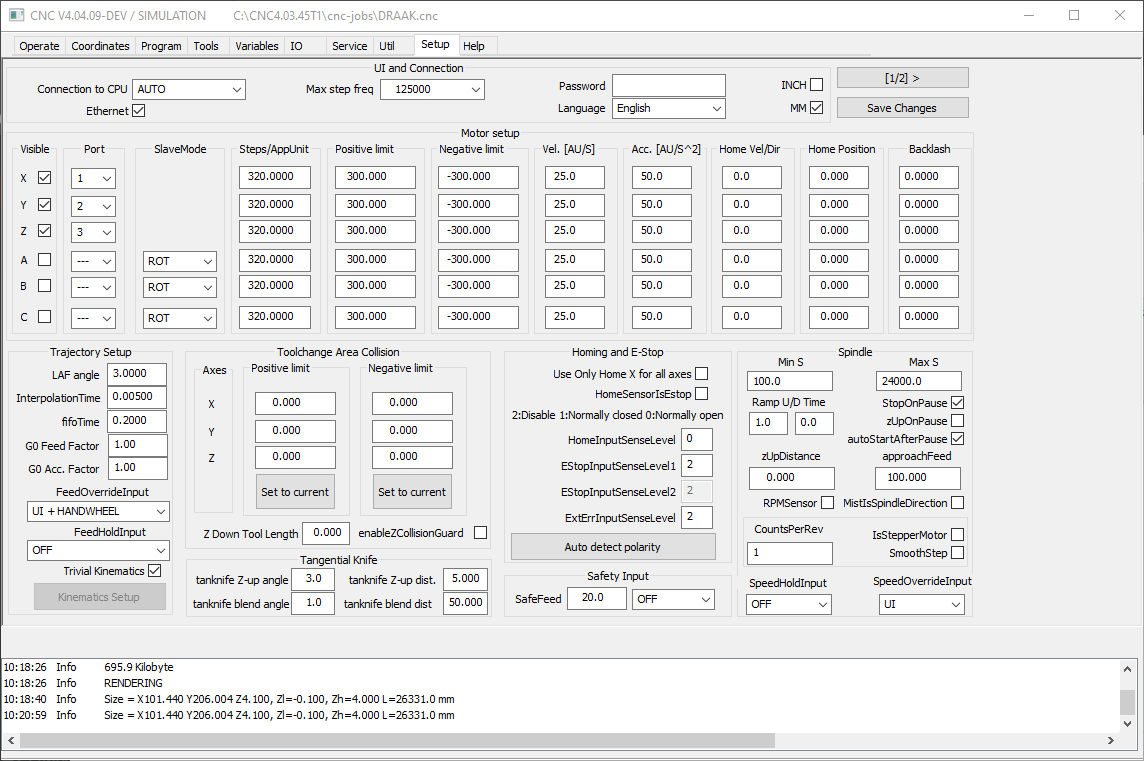

- Slave axes, for systems with dual motors (tandem) on X, Y or Z axis.

- Special homing sequence for tandems, sets tandem straight.

- Tangential knife, you need to program only X.Y coordinates and the tangential knife follows, also in circles and lifts automatically up when needed.

- Backlash compensation.

- Spindle proportional ramp-up time.

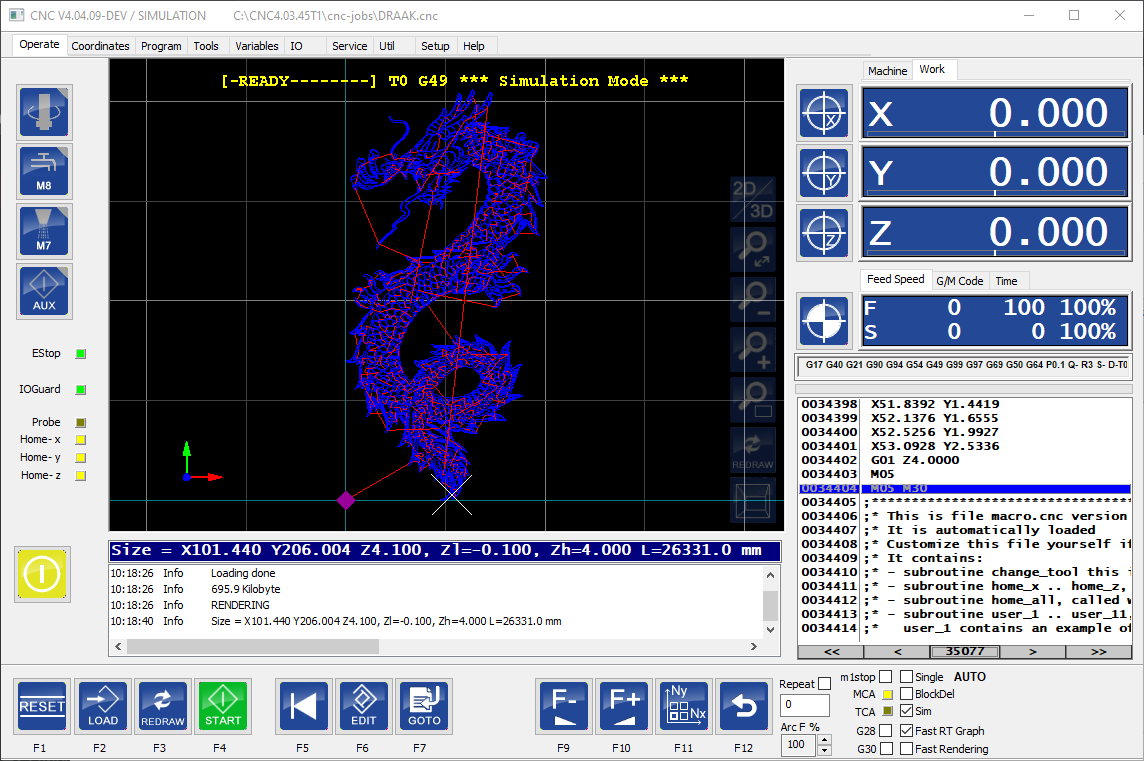

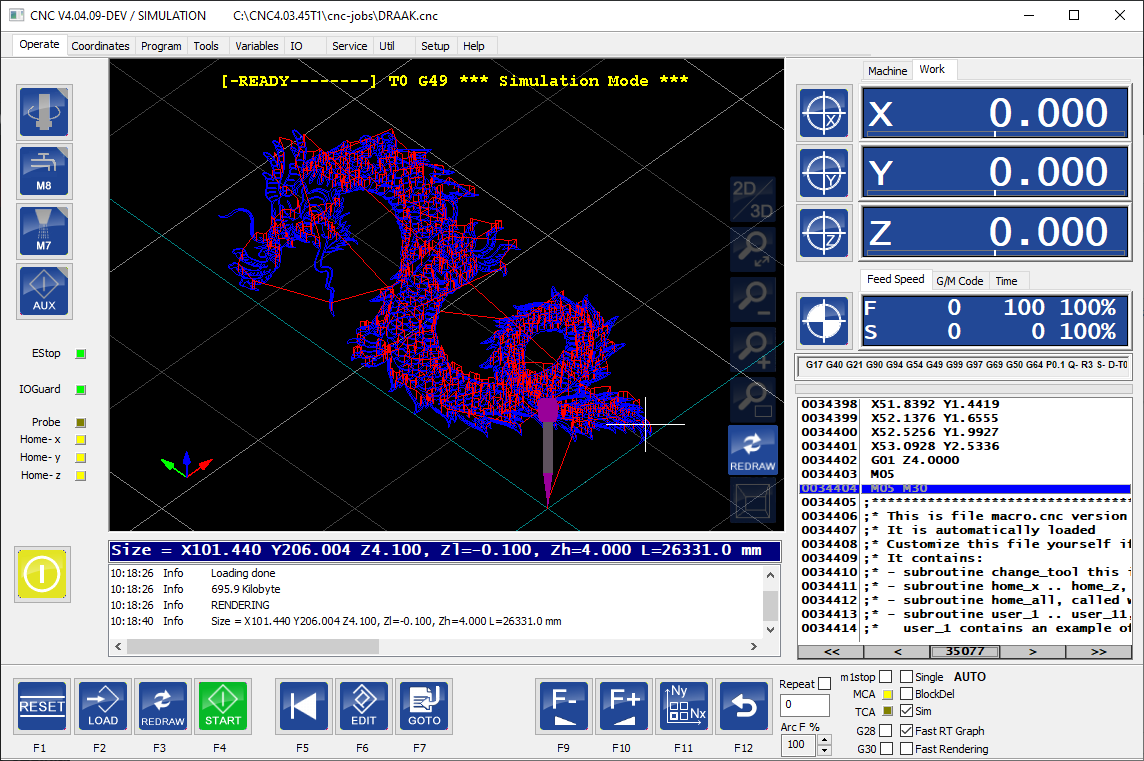

- Collision detection when the g-code job is loaded prevents machine damage.

- Running time estimation when the job is loaded.

- Thread cutting (Lathe).

- OpenGL graphics allows real-time PAN/ZOOM/ROTATE

- G-code is EMC compatible, RS274NGC, can be used with all CAM software’s so far.

- G-code extensions with IF..THEN, WHILE..ENDWHILE, SUB ENDSUB, GOSUB.

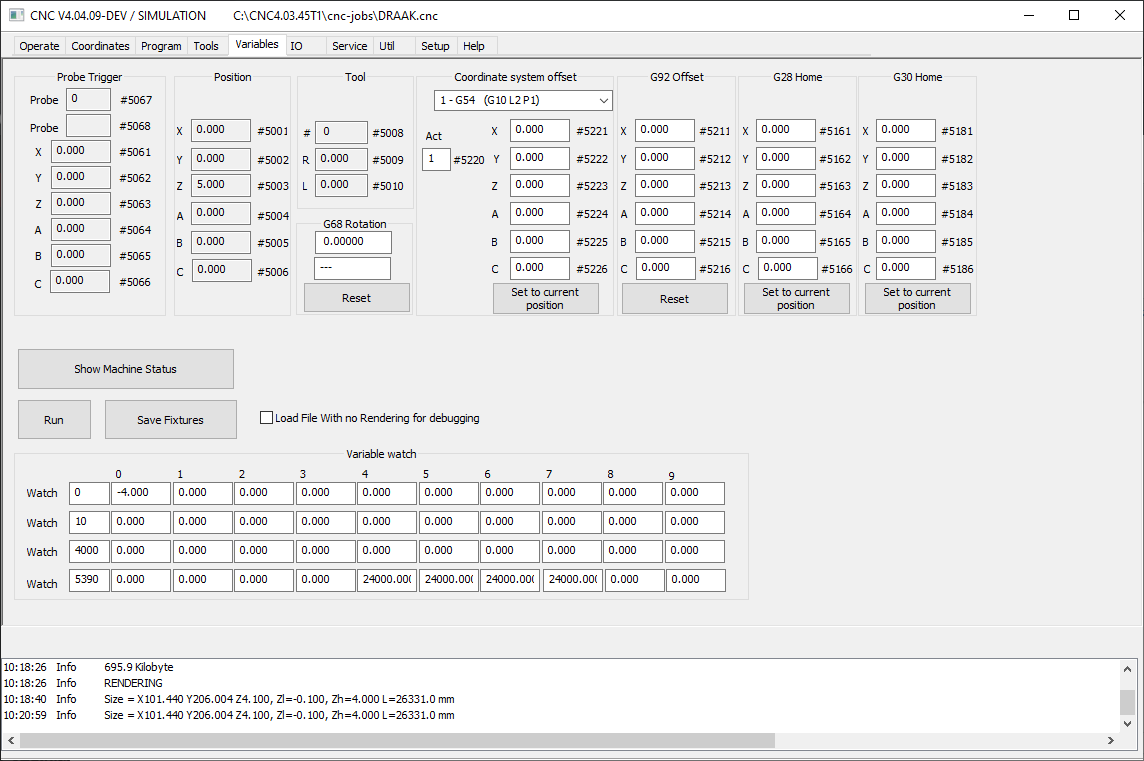

- G68, Zeroing with rotation, accurate setup of clamping device no longer necessary.

- Super long file mode allows endless files, tested with 100.000.000 lines g-code.

- User interaction from G-Code with DlgMsg command and a lot more.

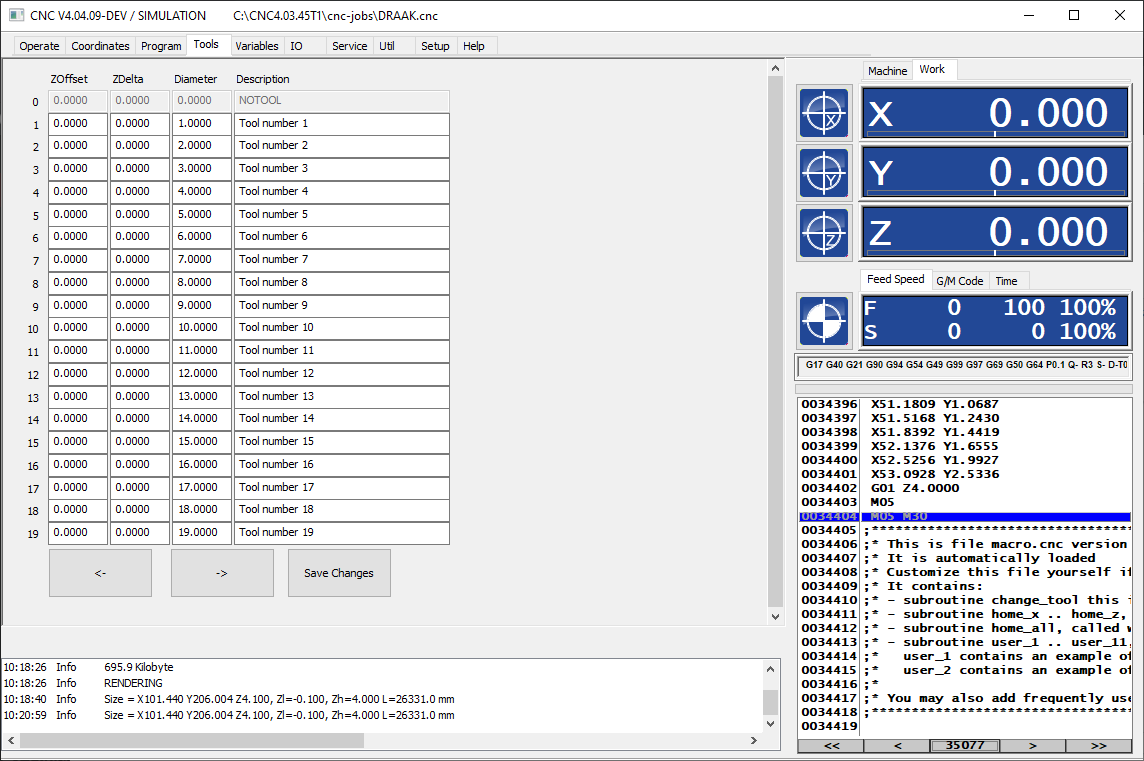

- Automatic tool change can be programmed entirely in G-code.

- Pause, Jog away, resume running in the middle of the g-code run.

- Handwheel jog with position and velocity mode.

…so now download the software and try it for you self HERE.